Project Convey

The Future Proof Automobile Research Project

October 2016

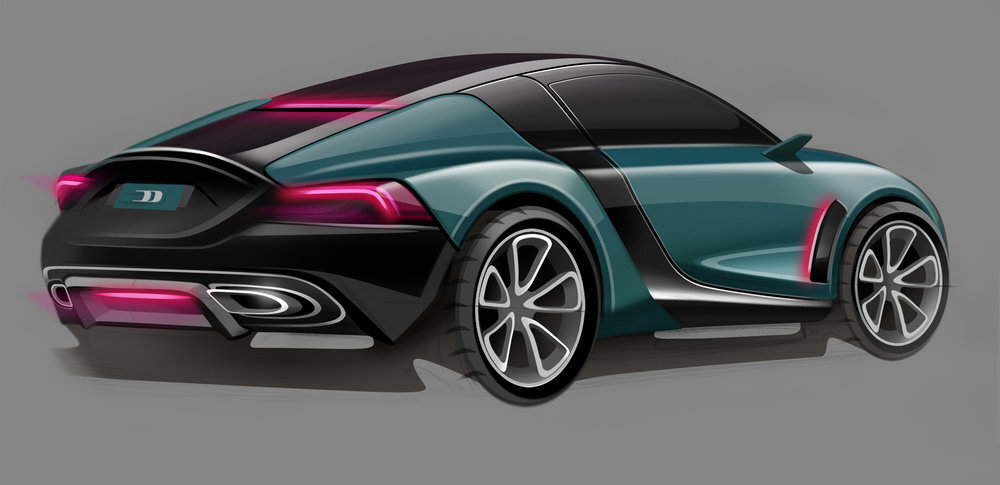

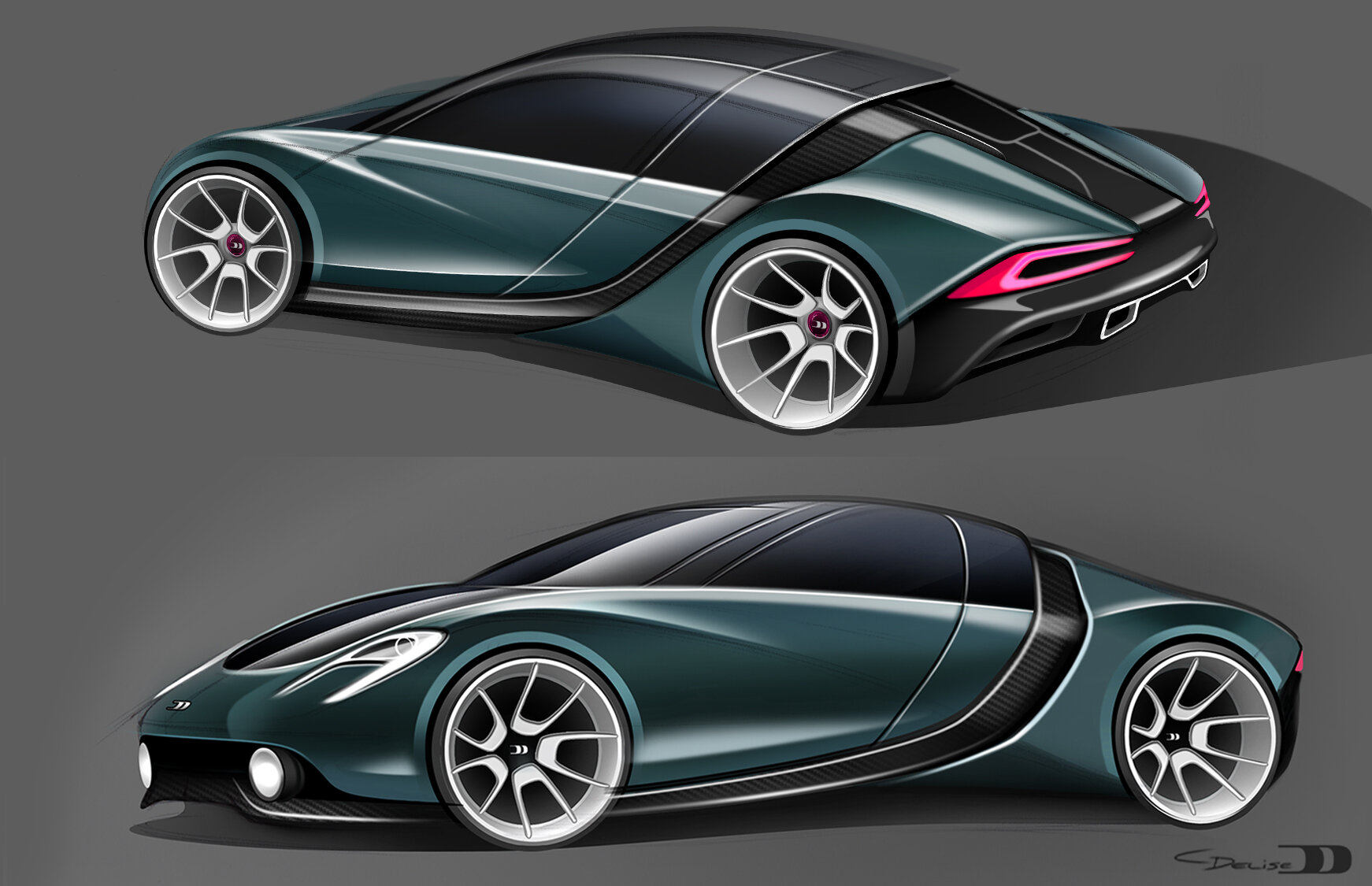

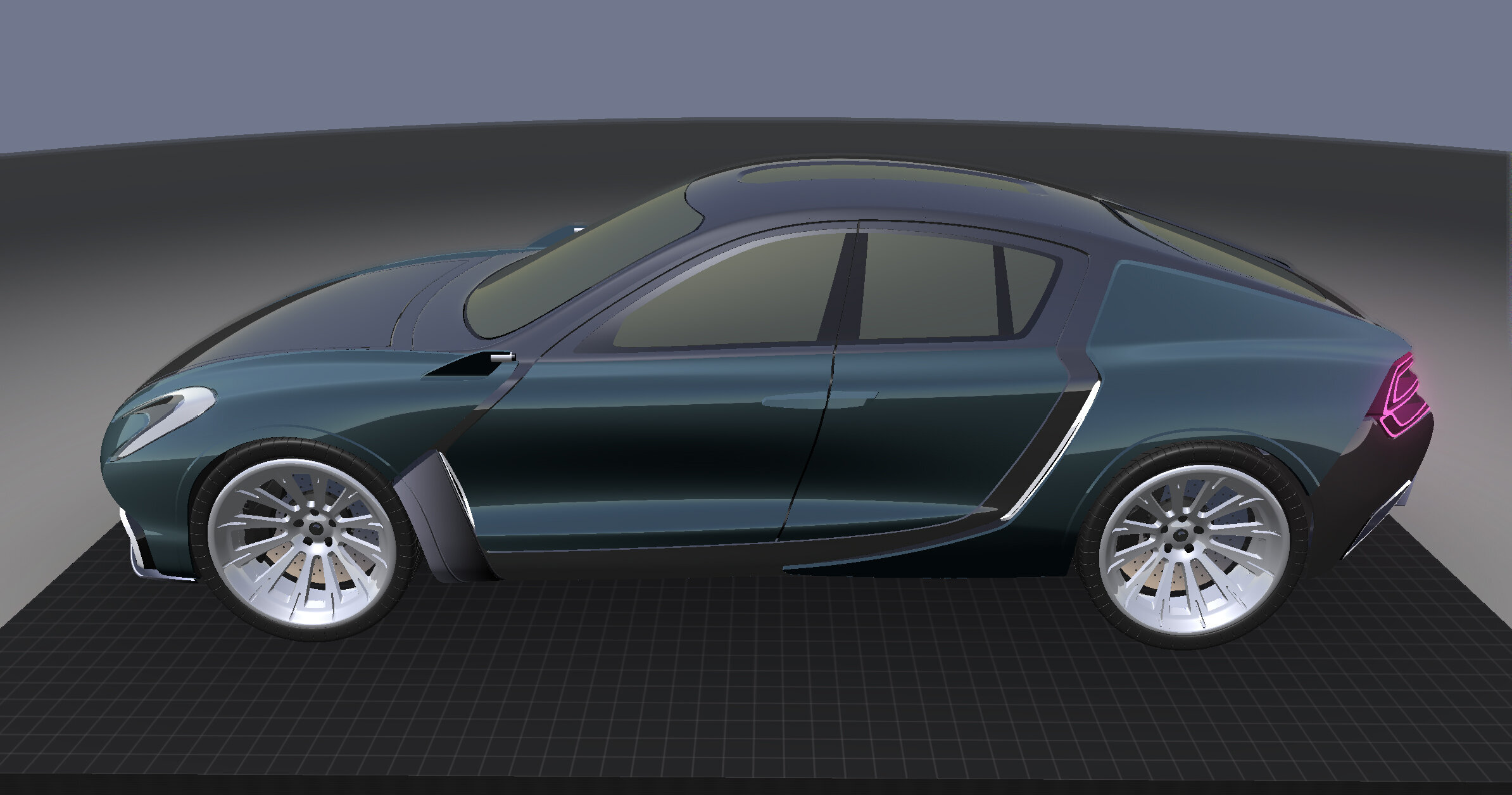

This is the vision for a fundamentally different form of car concept. Convey presents an alternative route for the story of the automobile. It is a question posed, an opportunity challenged. Our aim was to design a car which faithfully uphold the best of where we have come from while being adaptable to what will drive us in the future.

As designers, we are driven to create something of beauty.... as enthusiasts, we are drawn to impressive performance. The dream of the ideal car is bigger than seductive style, or outrageous speed numbers- what is of most significance is its role in the story of all these elements combined- That influence is what reaches us, the drivers.

One of the most pressing questions in the automotive industry is what will drive us in the future...How quickly will new innovation find its' way into market? Optimists predict it will happen overnight, others proclaim we still have a long journey ahead of us....the only consensus seems to be that the future of the industry is unpredictable.

Mission : Adaptability as Priority.

The Automotive Industry has been using various forms of modularity for its own benefit since the very beginning. Why has the functionality not been extended to the end user?

Simply put- The business case is not there....Obsolescence has long been established as the only cost effective way to maintain new car sales, and it simply made little sense to spend additional expense to effect or alter that model. We believe that for the first time in a century- the benefits of a more active and user-based form of modularity, aimed at curbing obsolescence and extending vehicle life cycles, could afford the manufacturers more advantages than previously imagined.

The largest gamble and cost risk in manufacturing a vehicle is which direction in drivetrain and technology. Faced with a five-ten year commitment, capital development costs and miscalculating demand is what kills a vehicle model. What if there was a way to mitigate this risk and increase sustainability? The implementation of the Convey concept model would allow the manufacturer and supply chain to reintroduce new platforms more actively throughout the life cycle of each generation of vehicles all while increasing consumer satisfaction and retention.

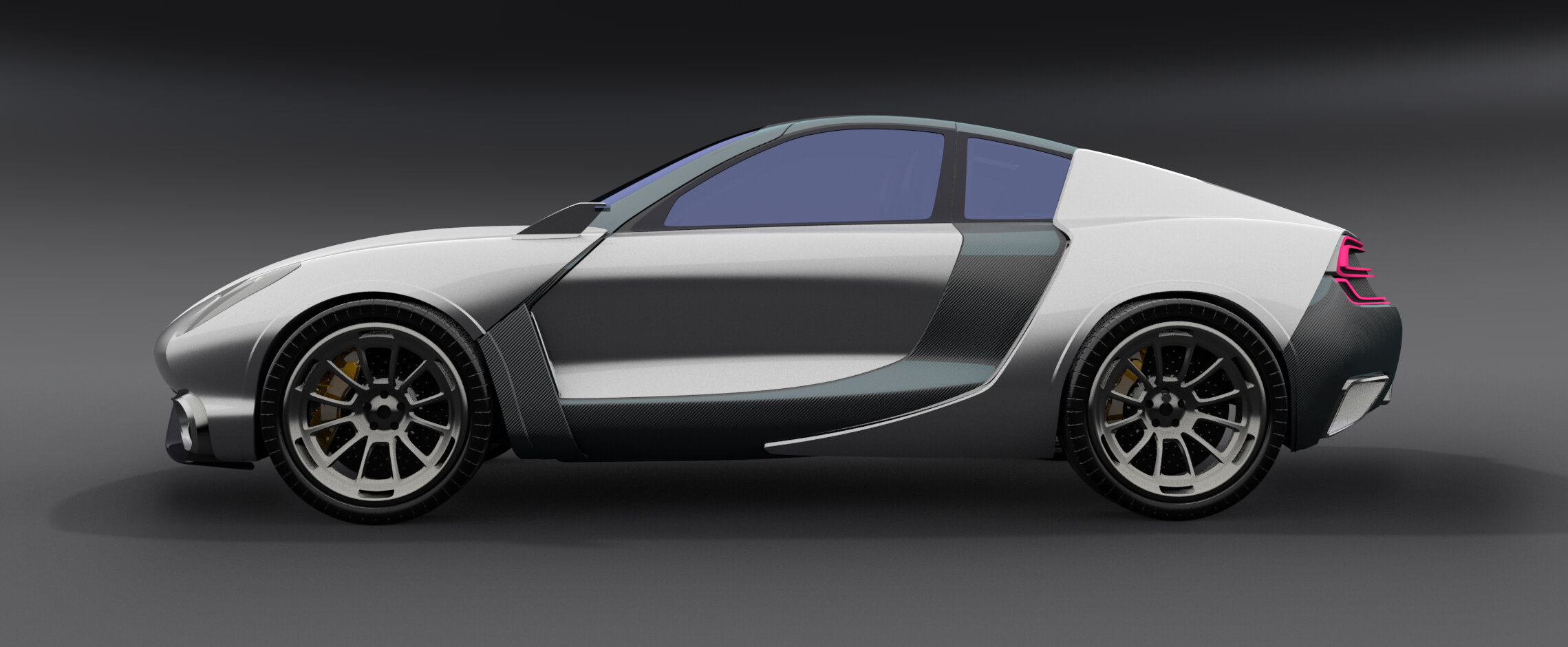

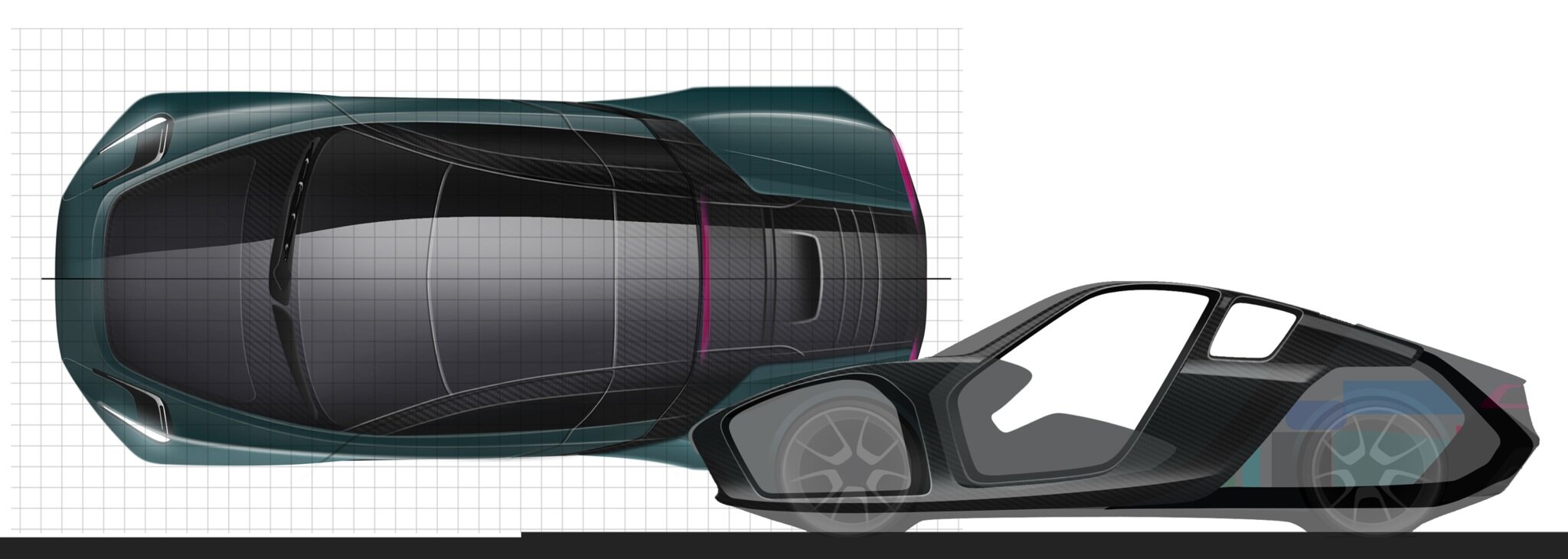

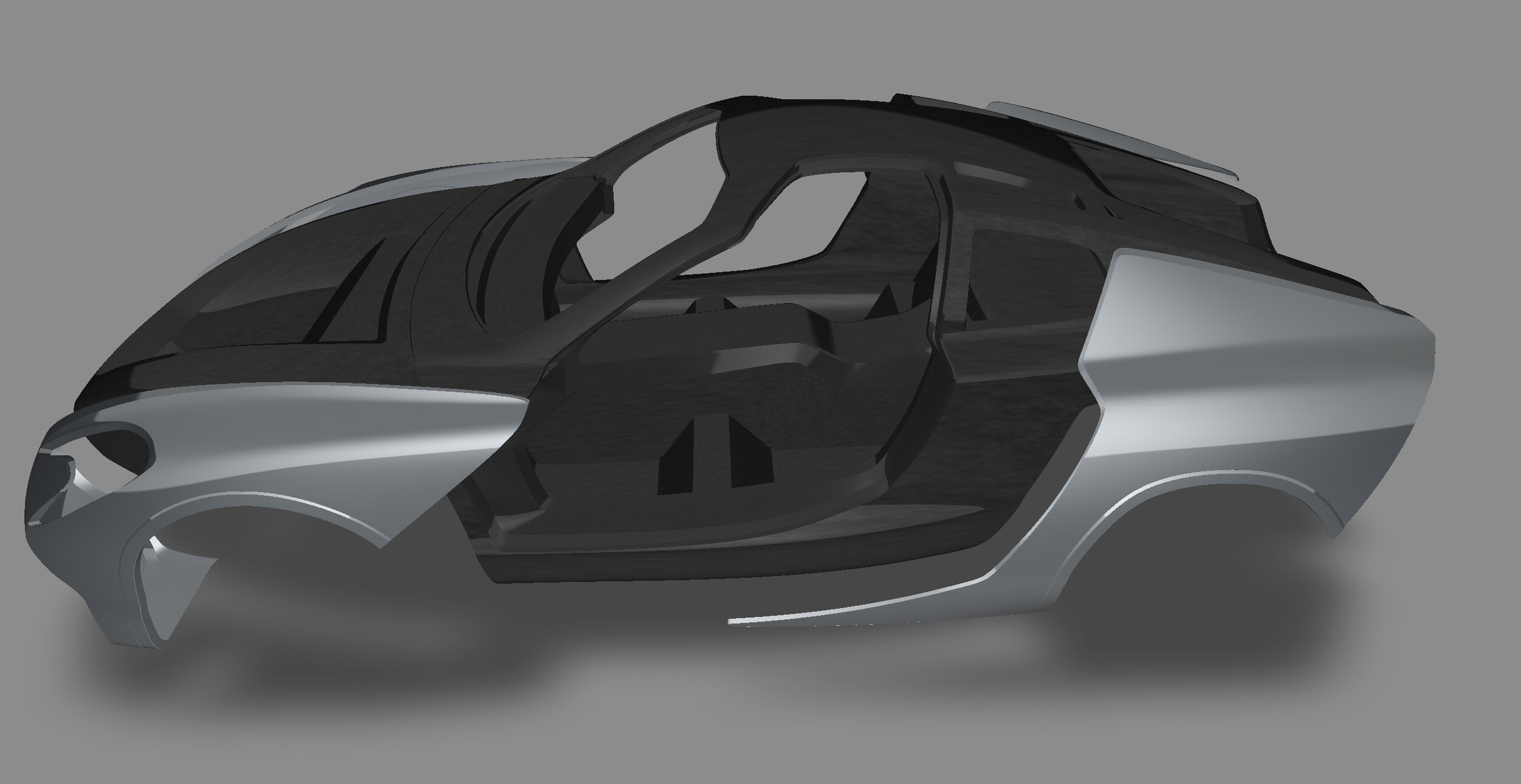

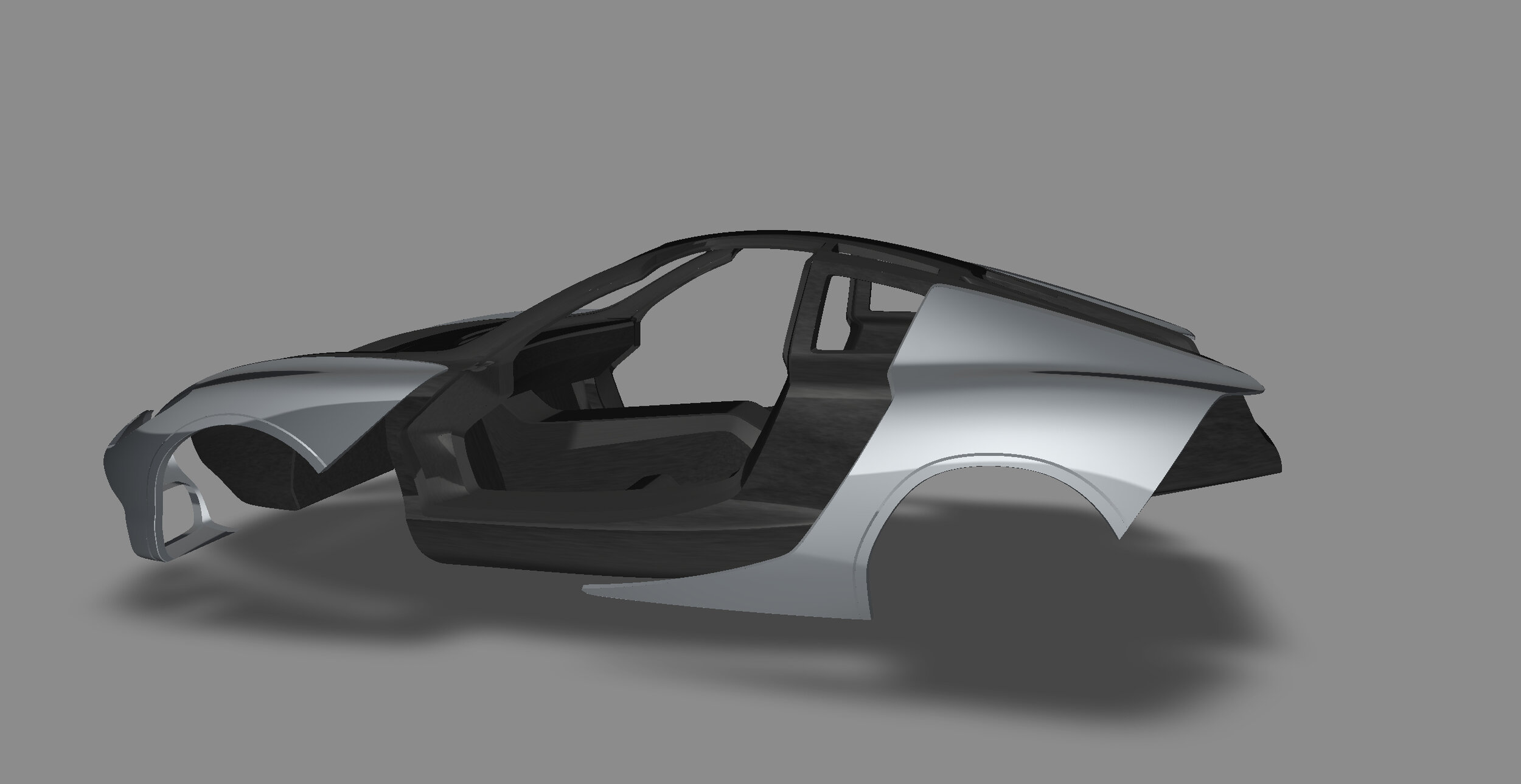

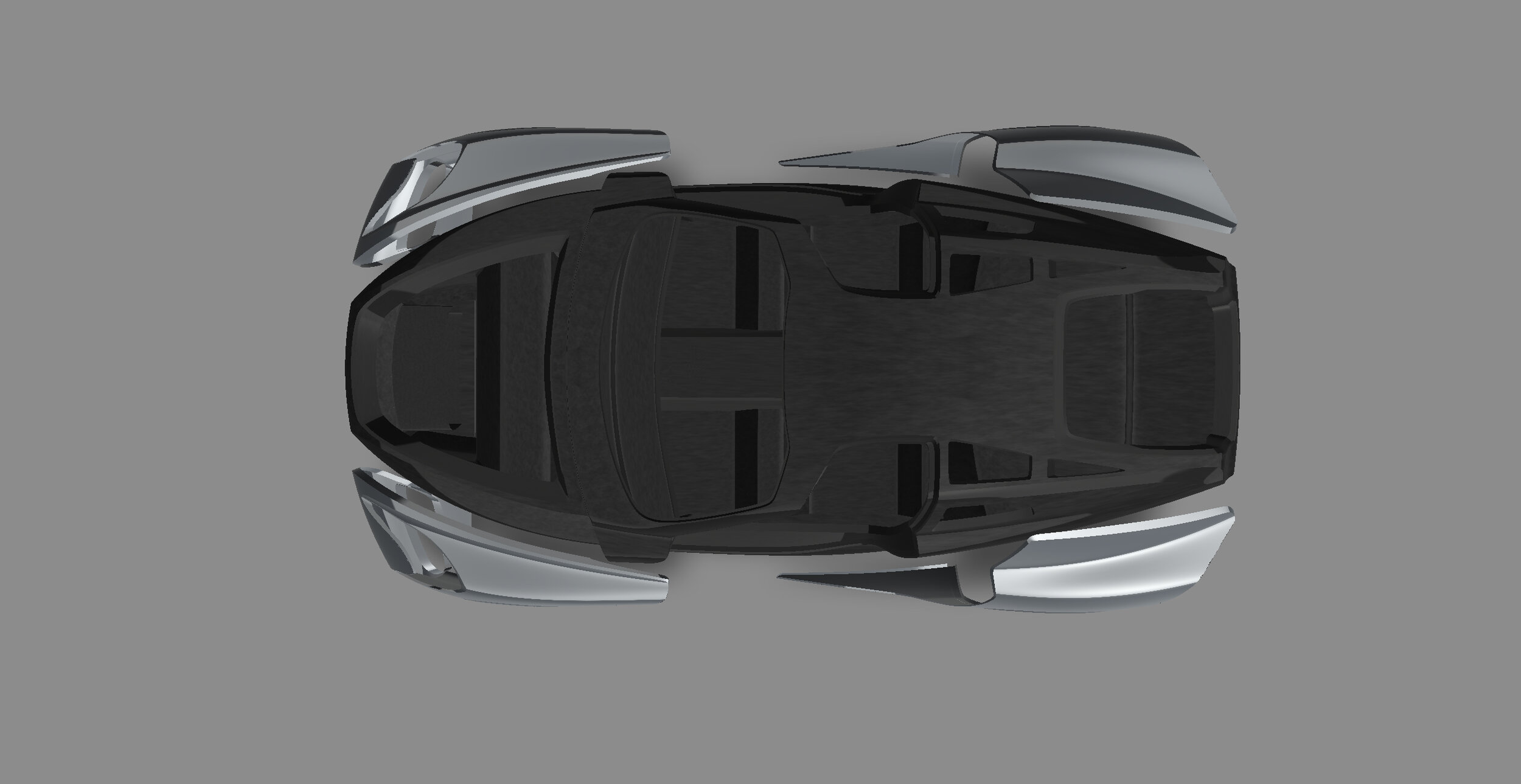

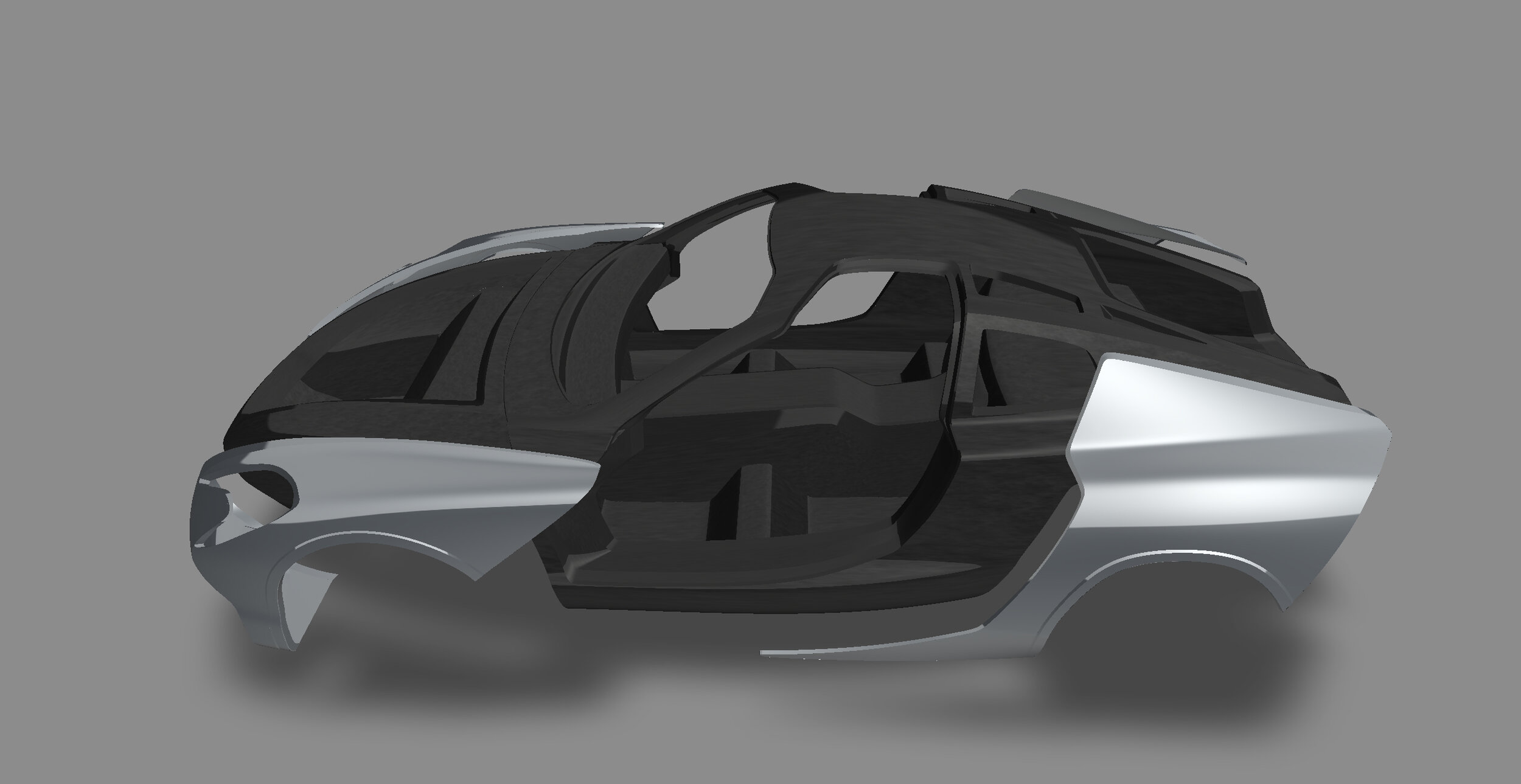

Every aspect of Convey is conceived to optimize modular adaptability- from the chassis drivetrain to exterior body panels.

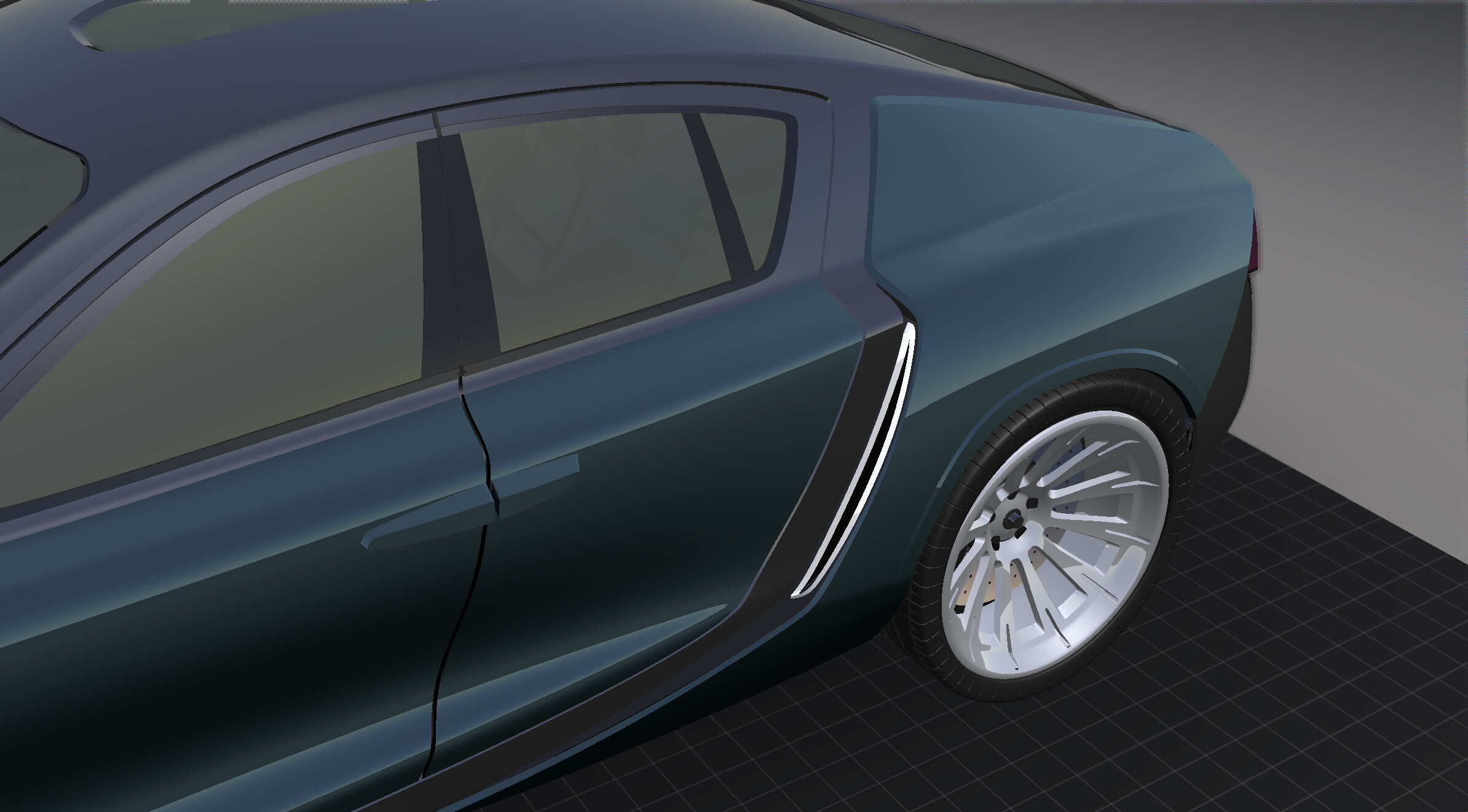

Assembly processes are designed for mounting and remounting multiple times over the life cycle of the vehicle.

Updates in exterior surfacing for aesthetic facelifts, or aerodynamic updates are possible, as well as capability to integrate updated LIDAR sensors or crash safety regulations.

Modular fenders accommodate for future changes in wheelbase, track width, and suspension geometries.

Dynamic Systems Communication

One of the driving technology advancements behind Concept Convey is the inherent benefits in simplifying the communication between different systems of the car. This has only recently been made possible due to the standardization of drive-by-wire operational controls and the rise in efficiency of software modules. The increased capabilities of these systems gives Convey an opportunity to expand the functional flexibility of the individual networks within the car. While traditional vehicle drivetrain electrical connections number in the thousands, today 100% of the drive controls and inputs can now be channeled through a single BUS- umbilical chord. This enables a simplified and separate interface between the main drivetrain electrical power systems, and the main operational systems such as lights, media, and amenity accessories.

The Key Advantage to the Convey system is the vehicle's ability to seamlessly swap drivetrains throughout its' life cycle. The DRIVE MODULE is designed from the beginning to accommodate a variety of powertrains- Hybrid, ICE, EV, Hydrogen, and beyond. This will allow for both the manufacturer and consumer to quickly adapt to ever changing advances in infrastructure and innovations across the entire fleet of vehicles in use.

These two systems could easily function independent of each other, splitting the responsibilities between the main body cabin, and the drive module. A closed loop drive module means that the powertrain of the vehicle can operate self sufficiently, and be ‘swapped‘ out without the need to interfere with the other systems of the main body, while still offering communication when connected.